Wholesale goods with your print

We have been working in the textile printing market for about 9 years. We always try to provide our customers with the best prices for bases and printing. When you contact us, you do not need to think about where you can get the basics for printing - we have everything. We also have our own sewing workshop and a fleet of equipment for any type of image application. We will always advise you on which type of application is suitable for your order, provide print samples, develop a design, complete the order as soon as possible and deliver it to you within the agreed time.

We use various printing methods, we will select the technology that is most beneficial for you and is ideal for your design:

Direct printing

Photo

Сlose up photo

Production

Description

Direct digital printing (DTG) is the most modern printing technology. The pattern is printed by a textile printer directly on the garment. Water-based paints are used for printing and are absolutely safe to use. It is possible to print on both white and colored fabrics, on colored fabrics a white backing is pre-printed, then color is applied. Therefore, the image on colored fabrics is denser. Also, colored fabrics may have traces of a primer (a special liquid that is used to treat a colored T-shirt before printing so that white color can be printed on it.). After washing, traces of the primer disappear. Printing is possible only on products with a high content of cotton, at least 60-70%, on synthetics this type of printing is impossible, the paint will flow. Suitable for printing any kind of images.

Feature: the image on the clothes looks less bright than on the monitor screen, because the dye is absorbed into the structure of the fabric. On white fabrics, the image looks brighter than on colored and black fabrics.

Print speed: a white T-shirt is printed in 5-15 minutes depending on the format, a color one - 15-30 minutes.

Clothing care: on the first day, do not wash, wash in delicate mode, without bleachers and powder improvers, spin at minimum speed, do not wring.

Sublimation

Photo

Сlose up photo

Description

Sublimation printing. Printing is intended for synthetic fabrics and souvenir products (cups, puzzles, etc.). White fabric is used for clothes, it is possible to apply the image by sublimation on fabrics of a different color, but the colors will be distorted, so white fabric is used for the correct color transfer. First, the image is printed on paper with sublimation ink, after which it is transferred to the fabric under high temperature and pressure. The picture is bright, it is included in the structure of the fabric. This method makes t-shirts and raglans with a full seal. First, the cut is sealed, after which the T-shirt is sewn - as a result, the production time of such a T-shirt or raglan is 1-3 working days.

Clothing care: it is one of the most stable printing methods, there are no special requirements for care.

Textile flex skin

Photo

Сlose up photo

Production

Description

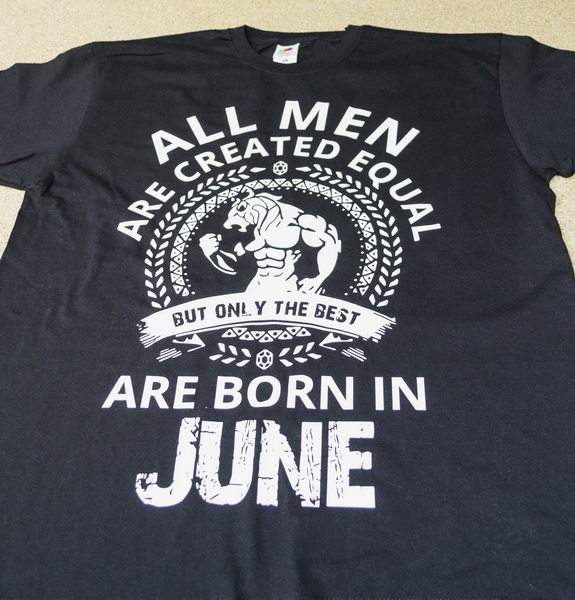

Flexo printing (flex, thermal application). First, the image to be applied is cut out on a plotter (cutter), after which everything superfluous is selected and only the image to be printed remains on the mounting film. After that, the image is transferred to the clothes using a heat press. Suitable for printing inscriptions and simple vector images that can be divided into 1-3 colors. It is not possible to make an image that is too small, less than 5 cm on the smaller side, and an image with very fine lines.

Print speed: printing takes anywhere from 10 minutes to infinity depending on the complexity of the sample and the image format.

Clothing care: wash in delicate mode, turn inside out, without bleaches and powder improvers, spin at minimum speed, do not wring.

Silkscreen

Photo

Сlose up photo

Description

Silkscreen. This printing method is used to print editions of 20 pieces of clothing with the same image. For this type of printing, a frame of each application color is pre-created, this process takes quite a long time, 2-3 days. When all the frames are prepared, printing begins. Special equipment is used for printing, because "carousel", each color should be applied to the clothes sequentially, before applying each next color, the previous one should be dried.

Print speed: lengthy preparation of the layout, the printing itself is quite fast, about 20-50 T-shirts per hour.

Clothing care: wash in delicate mode, without bleaches and powder improvers, spin at minimum speed, do not wring.

Thermal transfer

Photo

Сlose up photo

Description

Thermal transfer printing (thermal transfer). The image is printed on film with eco-solvent ink, after printing it is cut along the contour. Applying an image with a simple outline on dark fabrics is used instead of direct printing, because looks brighter compared to her. After printing and cutting, the remnants of unnecessary film are removed from the substrate and the image is transferred to the mounting film, after which the image is burned to the garment under a heat press.

Print speed: printing takes from 20 minutes to 40 minutes depending on the image format.

Clothing care: wash in delicate mode, turn inside out, without bleaches and powder improvers, spin at minimum speed, do not wring.

Tailoring

Scheme of work

- You are submitting an application

- We confirm your order and agree on the details

- You pay

- We fulfill it

- You pick up or deliver your order to you exactly in the agreed time

In order to calculate the circulation or find out any information that interests you, write to us by e-mail admin@mfest.com.ua or call the contact number of the center 0 (95) 180 55 85